Thordon, an elastomeric polymer alloy that combines strength/stiffness with high toughness and abrasion resistance. This combination results in a line of bearing products that is capable of carrying the operating loads found in this demanding application yet are flexible enough to resist wear due to 3rd particle abrasion.

The unique polymer structure is fully homogeneous so all the properties – abrasion resistance, self-lubrication, low coefficient of friction, resistance to vibration and shock loading – are consistent throughout the entire bearing wall thickness.

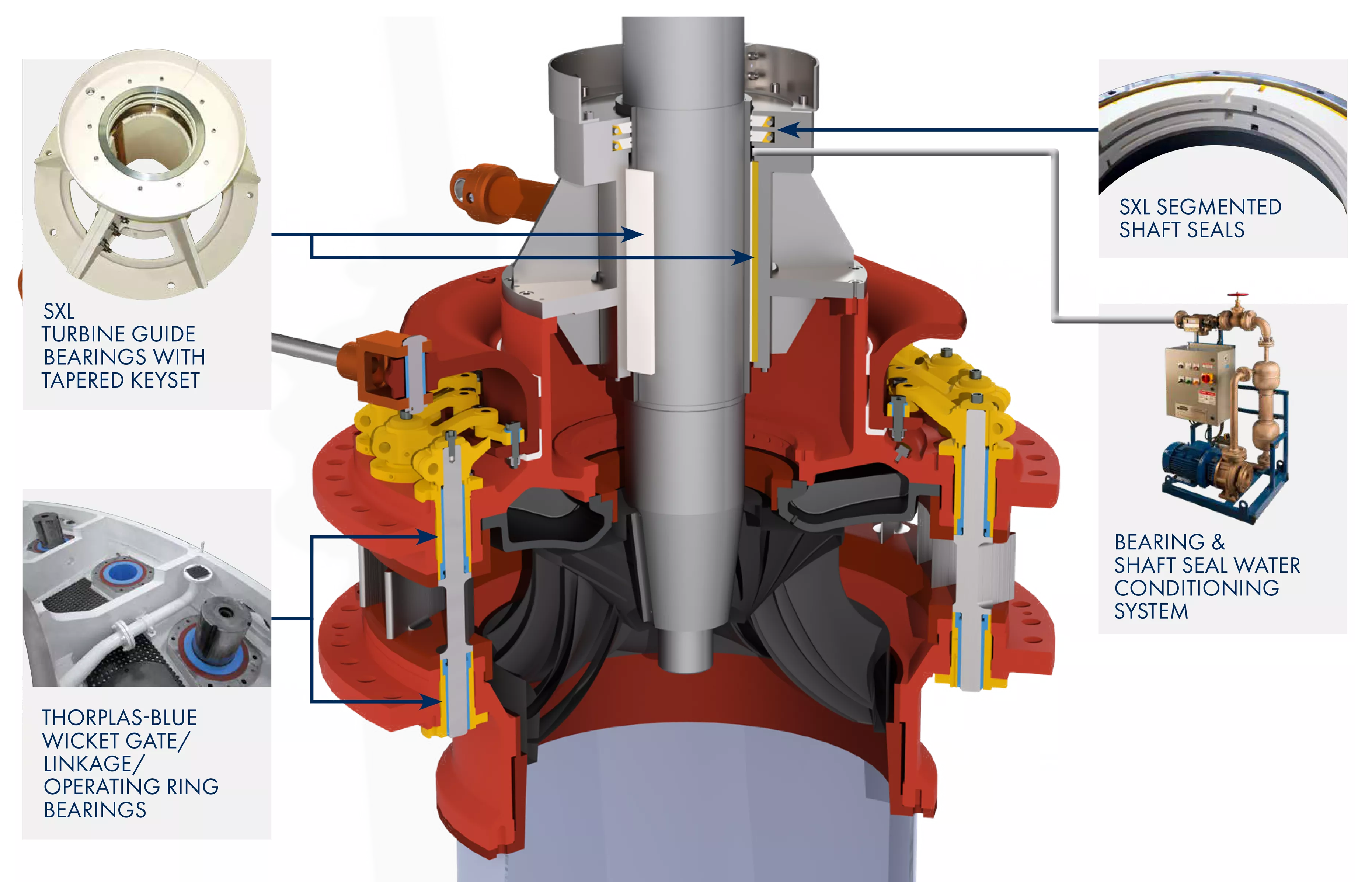

Thordon bearings are the superior choice for new turbines, upgrades from other bearings and full conversions of sealed oil systems. Choose Thordon SXL or GM2401, depending on the abrasive concentration in your water. We supply main shaft guide bearings:

Thordon Bearings offers two grades of water lubricated main shaft guide bearings for new turbines, upgrades from other bearings and full conversions from sealed oil systems.

Thordon SXL offers the lowest coefficient of friction, superior adhesive wear performance and good resistance to wear resulting from third particle abrasion.

Thordon GM2401 is specially formulated to provide superior wear resistance in abrasive water conditions, and significantly lower coefficient of friction compared to rubber.

Thordon bearings can be specified as an upgrade for rubber or other non-metallic bearings in existing waterlubricated bearing systems or as a complete conversion from sealed oil or grease lubricated systems to pollution-free water lubrication.

Thordon Wicket Gate and Linkage bearings operate wet or dry and eliminate the cost, maintenance and pollution risk associated with greased bearings.

Thordon SXL segmented axial and radial seals last longer and cut life-cycle costs compared to carbon seals.

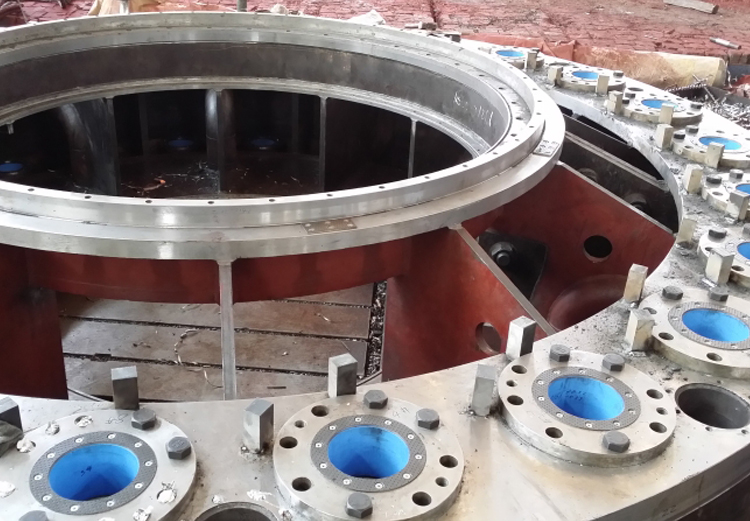

Design – Controlling the Bearing Environment